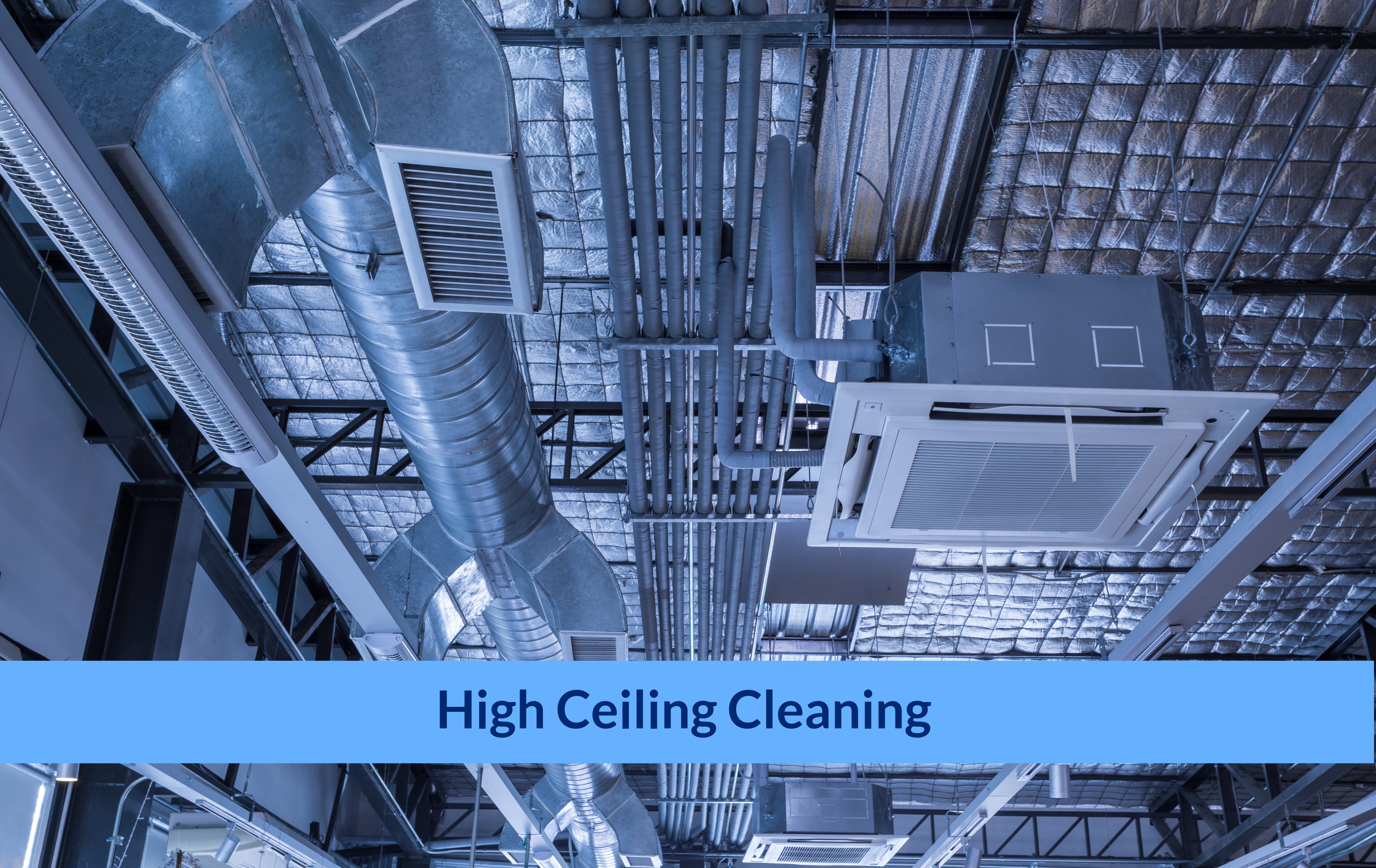

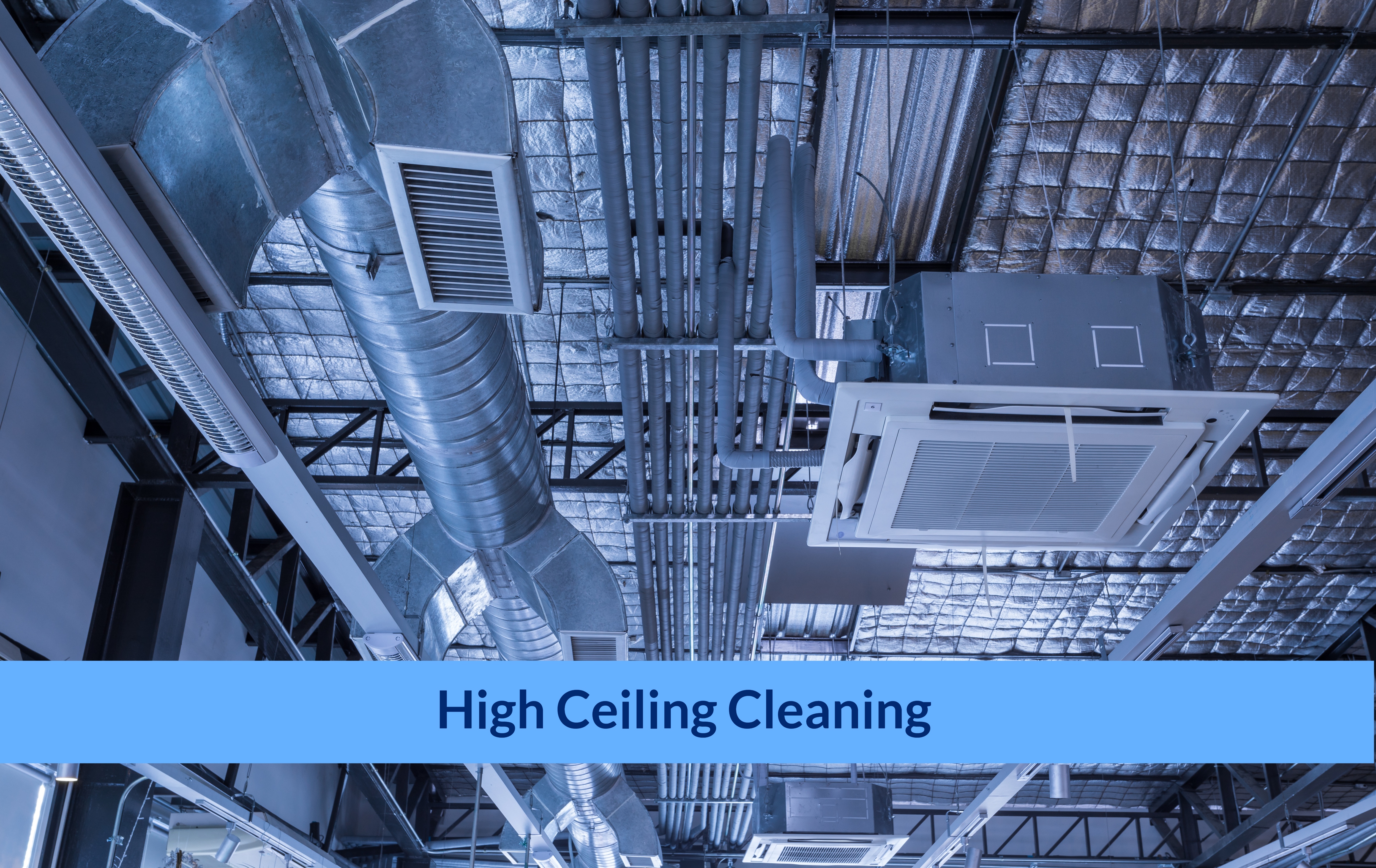

Does your facility have high ceilings (18′ or higher)? Did you know that your ceilings are a natural collection point for combustible dust? Combustible dust can be generated within almost any type of facility (industrial, office, or public) and is usually comprised of fine particulates containing metal, wood, plastic, rubber, etc.

As the name implies, combustible dust can, under certain conditions, create significant fire and/or explosion hazards. Since higher ceilings are harder to access, they are often overlooked or under-served within the traditional maintenance program. This can lead to significant safety and health risks for the facility’s occupants.

How can the problem of combustible dust be safely and effectively mitigated? A few of the basics associated with high ceiling maintenance:

High Ceiling Maintenance – Equipment

According to the National Fire Protection Association (NFPA) 654 Standard, the use of compressed air and traditional broom is not an effective approach to combustible dust removal. Those tools are especially ineffective when trying to remove combustible dust from high ceilings. Proper equipment would include:

- Explosion-Proof Vacuums: Effective removal of combustible dust requires the use of industrial, explosion-proof vacuums that are equipped with high-efficiency particulate air (HEPA) filters. It is important to select a vacuum that has been certified as “explosion-proof” by a Nationally Recognized Testing Lab (NRTL). NTRL is the only organization in the United Stated that can provide the “explosion-proof” certification.

- Extensions and Lighting: Use of high-reach equipment is usually necessary. This could include one or more of the following: extension platforms, scissor lifts, scaffolding, and A-frame ladders. It may also be necessary to use portable lighting for illumination of hard-to-see ceiling areas.

High Ceiling Maintenance – Safety

Safety is paramount when cleaning high ceilings, and the fact that you may be dealing with combustible dust adds significant risk to the process. Proper safety measures would include, but not be limited to, the following:

- Use of PPE: Use of required Personal Protection Equipment (PPE) is critical. This can include harnesses, safety glasses, hard hats, gloves, masks, etc. Applicable OSHA requirements should be consulted and followed.

- Spark Prevention: Minimize the risk of sparks, generated by static electricity, by making sure that all equipment is properly grounded. This should include vacuums, forklifts, lighting, extension cords, etc.

- Training: Make sure that persons performing your high ceiling maintenance have been properly trained. The training should be documented and conducted in a formal setting. Depending on your specific circumstances, you may want your ceiling cleaners to be licensed or certified by an external third-party certification body.

The above information covers just a few of the basics related to high ceiling maintenance. This information will hopefully provide you with the framework to begin construction of a program that will result in a safe approach to providing clean, safe, and healthy ceilings within your facility.

Are your higher ceilings hard to access? Are your high ceilings overlooked or under-served with your traditional maintenance program? Let us know in the section for comments below.

And if you need a customized, cost-effective Service Solution for your business, let SMO help. Request a Customized Service Solution today.

.jpg?width=220&height=135&name=Blog%20Listing%20Image%20(14).jpg)

.jpg?width=220&height=135&name=Blog%20Listing%20Image%20(4).jpg)

.png?width=180&height=138&name=Untitled%20design%20(25).png)